Three Phase Induction Motor:

The three phase induction motors are the most widely used electric motors in the industry. They run at essentially constant speed from no-load to full-load. However, the speed is frequency dependent and consequently, these motors are not easily adapted to speed control. We usually prefer dc motors when large speed variations are required.

Nevertheless, the 3-phase induction motors are simple, rugged, low-priced, easy to maintain and can be manufactured with characteristics to suit most industrial requirements. In this, we shall discuss working principle of 3-phase induction motors.

Like any electric motor, a 3-phase induction motor has a stator and a rotor. The stator carries a 3-phase winding (called stator winding) while the rotor carries a short-circuited winding (called rotor winding). Only the stator winding is fed from 3-phase supply. The rotor winding derives its voltage and power from the externally energized stator winding through electromagnetic induction and hence the name.

The induction motor may be considered to be a transformer with a rotating secondary and it can, therefore, be described as a “transformer type” ac machine in which electrical energy is converted into mechanical energy.

Construction of Three Phase Induction Motor:

Figure 8.1 shows the construction of three phase induction motor. A 3 phase induction motor has two main parts (i) stator and (ii) rotor. The rotor is separated from the stator by a small air-gap which ranges from 0.4 mm to 4 mm, depending on the power of the motor.

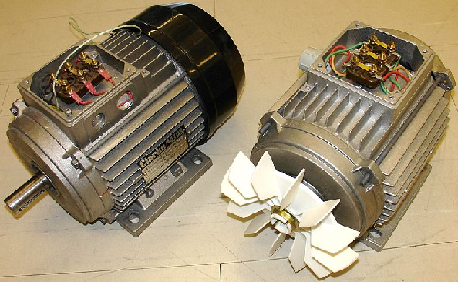

1. Stator :

It consists of a steel frame which encloses a hollow, cylindrical core made up of thin laminations of silicon steel to reduce hysteresis and eddy current losses. A number of evenly spaced slots are provided on the inner periphery of the laminations.[See Fig.(8.1)].The insulated connected to form a balanced 3-phase star or delta connected the circuit.

The 3-phase stator winding is wound for a definite number of poles as per requirement of speed. Greater the number of poles, lesser is the speed of the motor and vice-versa. When 3-phase supply is given to the stator winding, a rotating magnetic field(See Sec. 8.3) of constant magnitude is produced. This rotating field induces currents in the rotor by electromagnetic induction.

2. Rotor:

The rotor, mounted on a shaft, is a hollow laminated core having slots on its outer periphery. The winding placed in these slots (called rotor winding) may be one of the following two types:

(i) Squirrel cage type (ii) Wound type

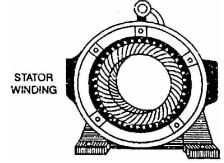

(i) Squirrel cage rotor: It consists of a laminated cylindrical core having parallel slots on its outer periphery. One copper or aluminum bar is placed in each slot. All these bars are joined at each end by metal rings called end rings.

This forms a permanently short circuited winding which is indestructible. The entire construction (bars and end rings) resembles a squirrel cage and hence the name. The rotor is not connected electrically to the supply but has current induced in it by transformer action from the stator.

Those induction motors which employ squirrel cage rotor are called squirrel cage induction motors. Most of 3 phase induction motors use squirrel cage rotor as it has a remarkably simple and robust construction enabling it to operate in the most adverse circumstances.

However, it suffers from the disadvantage of a low starting torque. It is because the rotor bars are permanently short-circuited and it is not possible to add any external resistance to the rotor circuit to have a large starting torque.

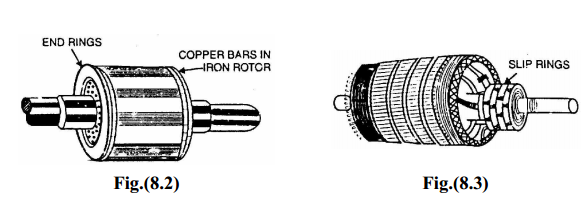

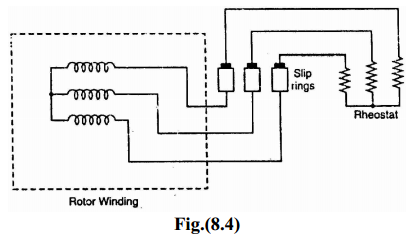

(ii) Wound rotor: It consists of a laminated cylindrical core and carries a 3-phase winding, similar to the one on the stator [See Fig. (8.3)].The rotor winding is uniformly distributed in the slots and is usually star-connected. The open ends of the rotor winding are brought out and joined to three insulated slip rings mounted on the rotor shaft with one brush resting on each slip ring.

The three brushes are connected to a 3-phase star-connected rheostat as shown in Fig. (8.4).At starting, the external resistances are included in the rotor circuit to give a large starting torque. These resistances are gradually reduced to zero as the motor runs up to speed.

The external resistances are used during starting period only. When the motor attains normal speed, the three brushes are short-circuited so that the wound rotor runs like a squirrel cage rotor.

Working Principle of Three Phase Induction Motor:

Speed of rotating magnetic field:

The speed at which the rotating magnetic field revolves is called the synchronous speed (Ns).Referring to Fig. (8.6 (ii)), the time instant 4 represents the completion of one-quarter cycle of alternating current Ix from the time instant 1.During this one-quarter cycle, the field has rotated through 90°. At a time instant represented by 13 or one complete cycle of current Ix from the origin, the field has completed one revolution.

Therefore, for a 2-pole stator winding, the field makes one revolution in one cycle of current. In a 4-pole stator winding, it can be shown that the rotating field makes one revolution in two cycles of current.In general, fur P poles, the rotating field makes one revolution in P/2 cycles of current.

The speed of the rotating magnetic field is the same as the speed of the alternator that is supplying power to the motor if the two have the same number of poles. Hence the magnetic flux is said to rotate at synchronous speed.

Three Phase Induction Motor Advantages:

(i) It has simple and rugged construction.

(ii) It is relatively cheap.

(iii) It requires little maintenance.

(iv) It has high efficiency and reasonably good power factor.

(v) It has self starting torque.

Three Phase Induction Motor Disadvantages:

(i) It is essentially a constant speed motor and its speed cannot be changed

easily.

(ii) Its starting torque is inferior to dc shunt motor.

Conclusion:

You have learnt Three Phase Induction Motor Construction & Working Principle. If you have any queries please comment below.

extremely helpful. thank you

Thank you for your kind words! I’m glad that you found the blog extremely helpful.

Thanks for the article, great information.

These provided information was really so nice,thanks for giving that post and the more skills to develop after refer that post. Your articles really impressed for me,because of all information so nice. Historic Fill NJ

Great post on three phase induction motors! We at Duke Electric often work on refurbishing this type of motor or finding replacement parts for clients. They come with a variety of options and capabilities and are known to be durable.

Great post on three phase induction motors! We at Duke Electric often work on refurbishing this type of motor or finding replacement parts for clients. They come with a variety of options and capabilities and are known to be durable.

Thank you for your comment and for sharing your experience with three phase induction motors. I’m glad that you found the post helpful. Three phase induction motors are indeed a popular choice for many applications due to their versatility and durability. It’s great to hear that your company specializes in refurbishing and finding replacement parts for these motors. Keep up the good work! If you have any further questions or comments, please don’t hesitate to reach out. Thanks again for reading and commenting!