Retardation or Running down Test On dc Machines:

This is the best and simplest method to find the efficiency of a constant-speed dc machine (e.g. shunt generator and motor). In this method, we find the mechanical (friction and windage) and iron losses of the machine. Then knowing the armature and shunt Cu losses at any load, the efficiency of the machine can be calculated at that load.

Retardation test Working Principle:

Consider a dc shunt motor running at no-load.

(i) If the supply to the armature is cut off but the field remains normally excited, the motor slows down gradually and finally stops. The kinetic energy of the armature is used up to overcome friction, windage and iron.

losses.

(ii) If the supply to the armature as well as field excitation is cut off, the motor again slows down and finally stops. Now the kinetic energy of the armature is used up to overcome only the friction and windage losses. This is expected because, in the absence of flux, there will be no iron losses.

By carrying out the first test, we can find out the friction, windage and iron losses and hence the efficiency of the machine. However, if we perform the second test also, we can separate friction and windage losses from the iron losses.

This textbook “Electrical Machinery by P.S. Bhimbhra” is the best in industry. Grab it now for very less price.

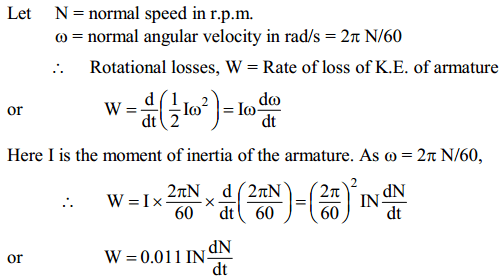

Theory of retardation test:

In the retardation test, the dc machine is run as a motor at a speed just above the normal. Then the supply to the armature is cut off while the field is normally excited. The speed is allowed to fall to some value just below normal. The time taken for this fall of speed is noted. From these observations, the rotational losses (i.e., friction, windage and iron losses) and hence the efficiency of the machine can be determined.

Let us illustrate the application of retardation test with a numerical example.

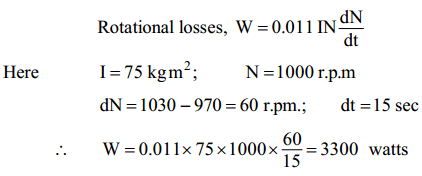

Suppose the normal speed of a dc machine is 1000 r.p.m. When retardation test is performed, the time taken for the speed to fall from 1030 r.p.m. to 970 r.p.m. is 15 seconds with field normally excited. If the moment of inertia of the armature is 75 kg, then,

The main difficulty with Retardation method is the accurate determination of the speed which is continuously changing.

Moment of Inertia (I) of the Armature:

In the retardation test, the rotational losses are given by;

W = 0.011 IN dN/dt

In order to find W, the value of I must be known. It is difficult to determine I directly or by calculation. Therefore, we perform another experiment by which either I is calculated or it is eliminated from the above expression.

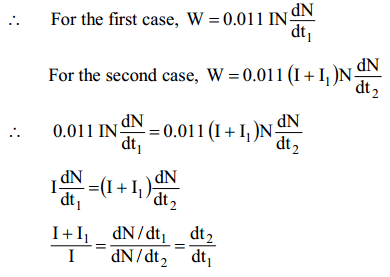

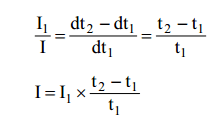

(i) First method:

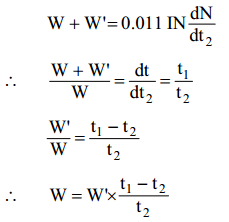

It is a fly-wheel method in which the value of I is calculated. First, retardation test is performed with armature alone and dN/dt1 is determined. Next, a flywheel of the known moment of inertia I1 is keyed on to the shaft of the machine. For the same change in speed, dN/dt2 is noted. Since the addition of fly-wheel will not materially affect the rotational losses in the two cases,

Since the values of I1, t1 and t2 are known, the moment of inertia I of the

armature can be determined.

(ii) Second method:

In this method, I is eliminated from the expression by an experiment. First, retardation test is performed with armature alone. The rotational losses are given by;

W = 0.011 IN dN/dt1

Next, the motor is loaded with a known amount of power W’ with a break. For the same change in speed, dN/dt2 is noted. Then,

Since the values of W’, t1 and t2 are known, the value of W can be determined.

This textbook “Electrical Machinery by P.S. Bhimbhra” is the best in industry. Grab it now for very less price.

Buy Now

Electric Loading in Retardation Test:

In a retardation test, the rotational losses W are given by;

W = 0.011 IN dN/dt

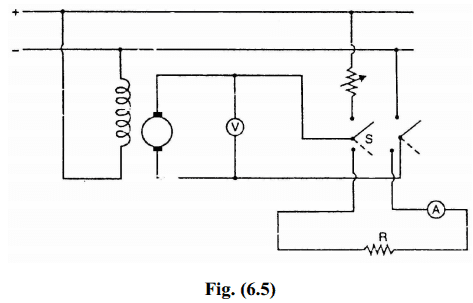

As discussed before, we can eliminate I (moment of inertia of armature) from the above expression by applying either mechanical or electric loading to the armature. The electric leading is preferred because of convenience and reliability. Fig. (6.5) illustrates how electric loading is applied to slow down the armature. The double throw switch S is thrown to the supply and the machine is brought to full-load speed. Then the switch S is thrown to the other side connecting a non-inductive resistance R across the armature. The supply now is cut off and the power dissipated in R acts as a retarding torque to slow down the armature.

Let V’ = average voltage across R

I’a = average current through R

The electric loading W’ (or extra power loss) is given by;

W’ = average voltage x average current = V’ I’a.

In the second method W should be W=W’*t2/(t1-t2)